Products

Optimized & Industry-ready Solutions

For All Your Complicated Needs

At TAWAKKAL, we specialize in innovative silicone rubber solutions designed to meet the demands of a wide range of industries. With cutting-edge technology and a commitment to quality, we provide customized products that align with your specific needs.

Product Categories

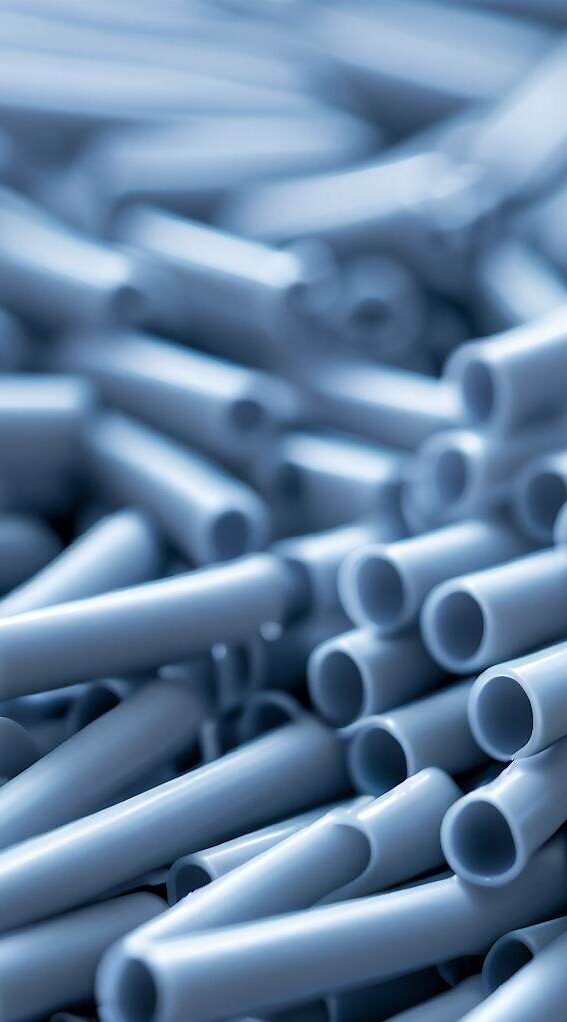

1. Silicone Extrusions

- High-performance silicone profiles for automotive, aerospace, construction, and industrial applications.

- Customized shapes and sizes with precise dimensional accuracy.

- Features: Heat resistance, flexibility, and durability.

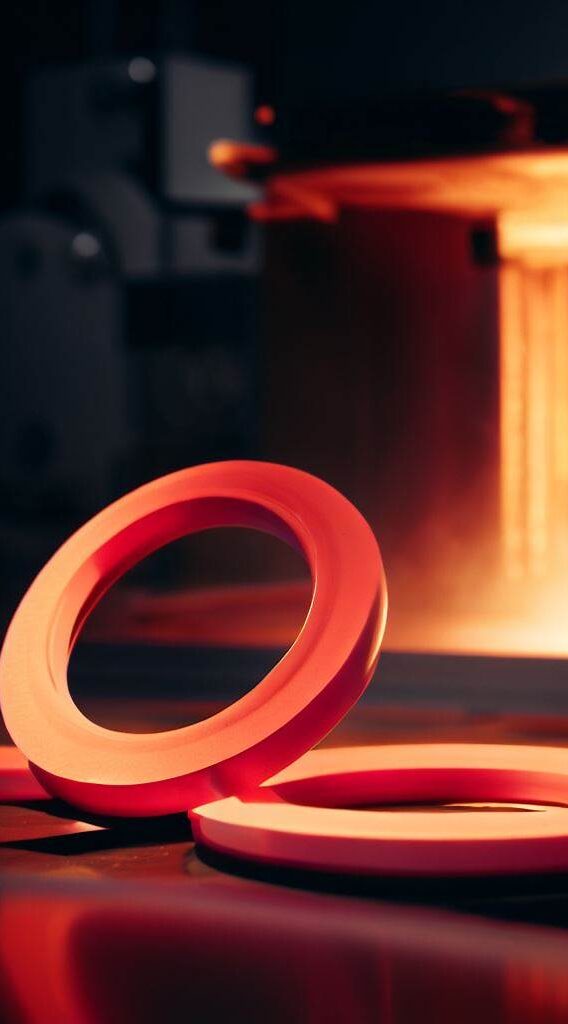

2. Compression Molded Products

- Silicone parts designed for high-pressure environments, ensuring reliable performance.

- Applications: Gaskets, seals, and specialized industrial components.

- Tailored designs for complex geometries and enhanced functionality.

3. 3D-Printed Silicone Components

- State-of-the-art additive manufacturing technology for rapid prototyping and small-scale production.

- Applications: Biomedical devices, microfluidic systems, and custom designs.

- Benefits: Speed, precision, and cost efficiency.

4. Injection Molded Silicone Products

- Superior-quality molded components for large-scale production.

- Applications: Electrical insulation, food-grade products, and automotive parts.

- Features: Uniformity, excellent mechanical properties, and high repeatability.

Key Features of Our Products

- Customization: Tailored to your specific property, size, and color requirements.

- Quality Assurance: Rigorous testing to ensure compliance with industry standards.

- Versatility: Solutions for diverse industries, including automotive, aerospace, biomedical, and oil & gas.

- Sustainability: Commitment to eco-friendly practices and sustainable materials.

Industries We Serve

Our silicone rubber products cater to a broad spectrum of industries, including:

- Automotive

- Aerospace

- Biomedical

- Construction

- Electrical

- Food & Dairy

- Agriculture

- Oil & Gas

Why Choose TAWAKKAL?

- Expertise in silicone rubber technology.

- Advanced manufacturing techniques.

- Focus on innovation and efficiency.

- Strong technical support and collaboration.