Aersospace and Defence

Our Products in Aerospace and Defence Industries.

Both silicone rubber and PTFE are essential materials in the aerospace and defense industries, providing solutions for sealing, insulation, lubrication, vibration control, and corrosion resistance. Their properties contribute to the reliability and performance of critical equipment and systems in these sectors.

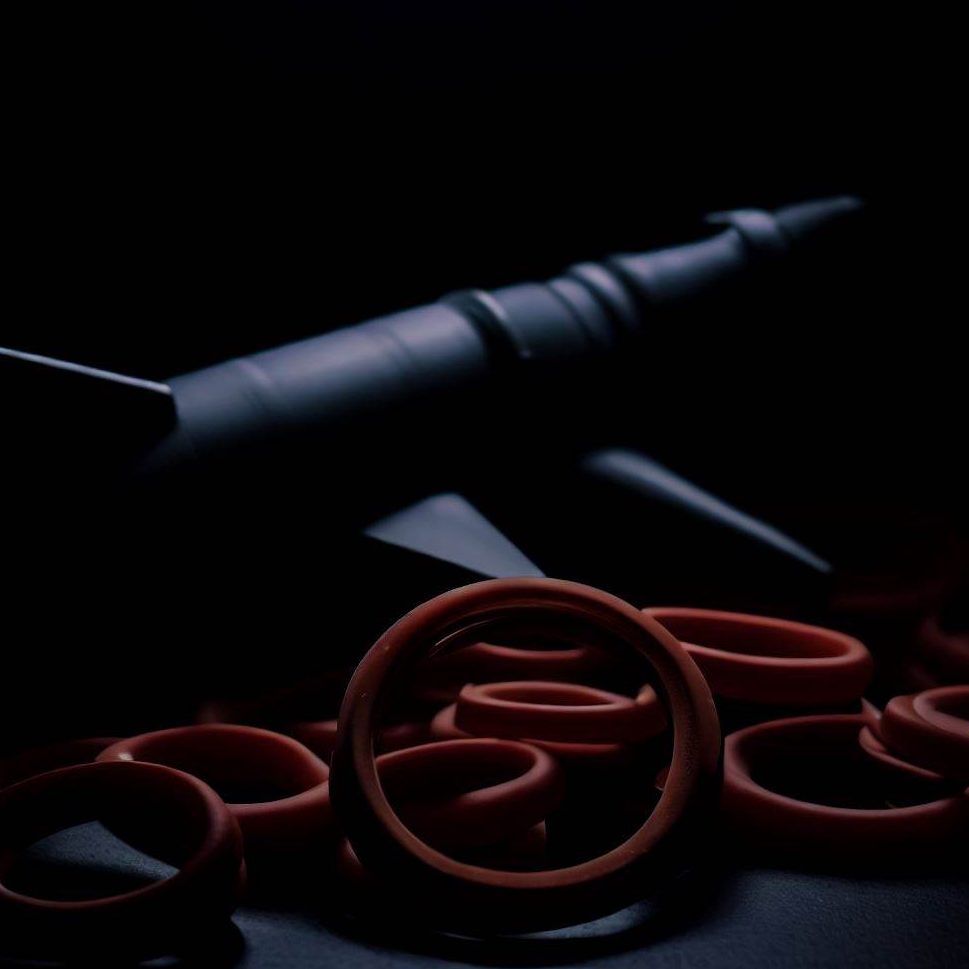

Seals and Gaskets:

Silicone rubber is widely used for creating seals and gaskets in aerospace and defense applications. It provides an effective barrier against moisture, chemicals, and extreme temperatures, ensuring the integrity of sensitive equipment and systems.

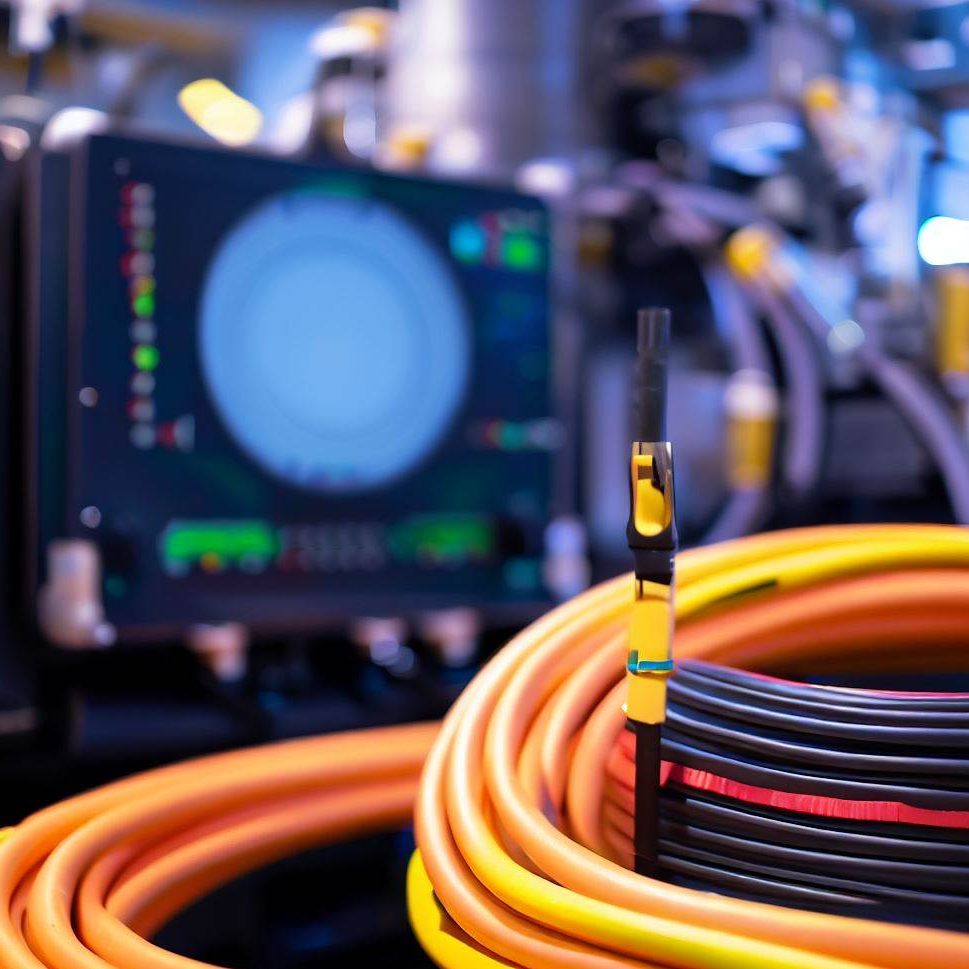

Electrical Insulation:

Silicone rubber is used for electrical insulation in aerospace and defense electronics due to its dielectric properties and resistance to high temperatures. It is employed in wires, connectors, and insulating components.

Vibration Dampening:

Silicone rubber is used to dampen vibrations and reduce noise in aircraft and defense machinery, contributing to a quieter and more comfortable environment.

Encapsulation:

Silicone rubber encapsulation is used to protect delicate electronic components from environmental factors such as moisture, dust, and shock in aerospace and defense equipment.

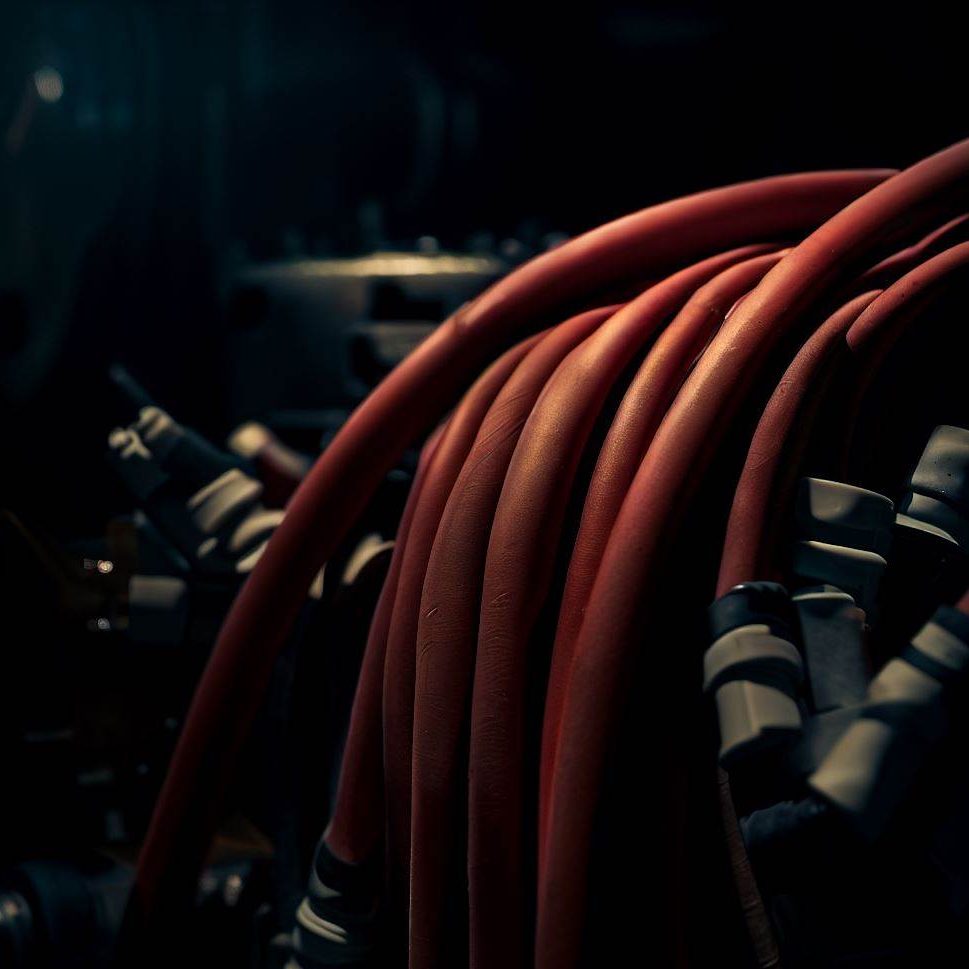

Cable and Wire Insulation:

Silicone rubber coatings and sleeves are applied to cables and wires in aircraft and defense systems to provide electrical insulation, thermal protection, and resistance to radiation.

Engine Components:

Silicone-based sealants and adhesives are used in aerospace engine assembly and maintenance due to their resistance to high temperatures and aviation fuels.